How Specialist Commercial Refrigerator Repair Can Increase Your Service Effectiveness

Wiki Article

Repairing Commercial Refrigeration Repair Work: Techniques for Quick and Effective Fixes

Understanding the typical problems that pester business refrigeration systems and having a toolkit of analysis methods at your disposal can make all the distinction in quickly recognizing and treating troubles. As we navigate with the details of fixing business refrigeration repair, we will certainly uncover the crucial strategies for solving concerns effectively, making certain that businesses can preserve optimum cooling performance and lessen downtime.Usual Commercial Refrigeration Concerns

Business refrigeration systems commonly experience a series of functional issues that can disrupt their performance and efficiency. One widespread issue is incorrect temperature level control, which can lead to food putridity and waste if not quickly attended to. This problem may stem from problems with the thermostat, evaporator follower, or condenser coils, needing thorough examination to pinpoint the source. One more typical problem is inadequate airflow, often brought on by obstructions in the vents or a malfunctioning follower. Poor airflow can cause temperature variances within the fridge or fridge freezer, influencing the top quality and security of saved products.Moreover, cooling agent leakages position a substantial concern as they not just impact the cooling capability of the system but likewise contribute to ecological injury. Regular cleansing and upkeep can assist avoid this concern and prolong the life-span of the refrigeration system.

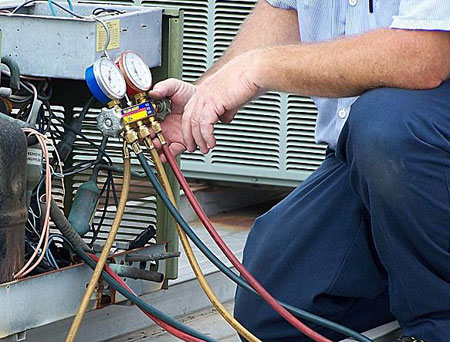

Analysis Devices and Techniques

Effective troubleshooting of commercial refrigeration systems depends heavily on utilizing specialized diagnostic devices and methods to determine and fix underlying issues efficiently - commercial refrigeration repair. Furthermore, leakage discovery tools like electronic leakage detectors or ultraviolet dye packages are crucial for locating refrigerant leakages that can lead to system ineffectiveness.Techniques such as stress screening making use of manifold evaluates can figure out if the system has the right refrigerant fee and identify any kind of leaks. Visual examinations of parts for indicators of deterioration, ice, or wear accumulation are likewise basic in identifying problems. Information loggers can be utilized to keep track of system efficiency over time and spot patterns that may show repeating troubles. By combining these analysis tools and strategies, specialists can properly fix commercial refrigeration systems and supply exact and quick fixings, decreasing downtime and making sure optimal system efficiency.

Quick Repairs for Refrigeration Problems

When encountered with refrigeration problems, technicians can carry out quick fixes to deal with typical problems quickly and efficiently. One typical fast fix is looking for an unclean condenser coil, which can trigger the system to run inefficiently. Cleansing the condenser coil routinely can enhance the system's efficiency and protect against overheating. One more fast repair is making certain that the refrigerator is not overwhelmed, as congestion can restrict airflow and lead to temperature variances. Changing the shelving to permit correct air circulation can commonly solve this issue. In addition, checking the door seals for any type of indicators of wear or damages and changing them if necessary can aid preserve the honesty of the seal and prevent air leaks. If the refrigeration unit is not cooling down properly, inspecting and changing the thermostat setups might provide a quick solution prior to more comprehensive troubleshooting is required. By applying these quick repairs, professionals can attend to typical refrigeration problems efficiently and keep business refrigeration systems running efficiently.

Preventative Maintenance Tips

Executing a proactive upkeep timetable is vital for ensuring the long life and optimal efficiency of industrial refrigeration systems. Regular maintenance not just assists stop expensive break downs yet also ensures that the tools operates successfully, saving power and minimizing overall operating expense. Here are some preventative maintenance tips to maintain commercial refrigeration systems running smoothly:

Check and Change Filters: Filthy filters can limit air flow, making the system work tougher and potentially creating damages. Inspect and replace filters frequently to stop problems.

Inspect Seals and Gaskets: Leaking seals and gaskets can lead to visit this web-site temperature variations and energy waste. Evaluating and replacing harmed seals can assist maintain constant temperature levels.

Professional Assistance and Provider

To maintain the optimum efficiency achieved through normal preventative maintenance, looking for expert assistance and services for commercial refrigeration systems is necessary. Professional technicians possess the knowledge and specialized knowledge required to identify and attend to complicated problems efficiently. When encountering tough refrigeration problems, relying upon expert assistance can save both money and time in the future.Professional services use benefits such as access to sophisticated devices and devices, guaranteeing that repair services are performed efficiently. Furthermore, professionals are trained to follow market policies and safety criteria, reducing the risk of crashes and ensuring conformity with lawful needs.

Conclusion

In conclusion, troubleshooting business refrigeration repair service requires a methodical technique to identifying typical concerns, using analysis devices and techniques, implementing quick solutions, and prioritizing preventative upkeep. Professional assistance and services might be required for even more complex troubles - commercial refrigeration repair. By adhering to these techniques, companies can guarantee their refrigeration systems operate effectively and efficiently, minimizing downtime visit this page and possible lossesRecognizing the common issues that pester business refrigeration systems and having a toolkit of diagnostic techniques at your disposal can make all the distinction in promptly determining and correcting issues.Efficient troubleshooting of business refrigeration systems counts greatly on utilizing specialized diagnostic devices and strategies to identify and solve underlying issues efficiently. By combining these analysis devices and techniques, professionals can effectively troubleshoot commercial refrigeration systems and provide fast and accurate fixings, minimizing downtime and making certain optimal system performance.

By applying these quick solutions, professionals can deal with typical refrigeration troubles efficiently and maintain industrial this article refrigeration systems running smoothly.

Additionally, expert assistance can aid extend the life-span of business refrigeration systems by determining possible concerns before they escalate.

Report this wiki page